Press

PAPER MACHINE

The design and construction of new press sections or the rebuilding of existing plants, in addition to ensuring the highest dryness level, have always been inspired by the following guidelines:

• Simplicity of execution and cost-effectiveness in management;

• Practicality and maximum operational safety.

The technical staff is always available to study, design, and create customized solutions that meet the most diverse needs.

- Uni Press

-

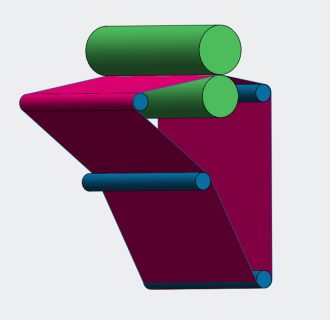

- BiNip/Combi Press

-

The BiNip press in all its variants is used to produce both fine paper and packaging grades, and for fine paper can be combined with a single-felted third press, while on packaging machine third press can be double-felted. Bi-Nip Press is designed to maximise water removal, efficiently transferring the web from the forming section to the dry part and increasing the quality of the paper.

Double-felted first press:

- prevents crushing and allows higher loads

- Increases efficiencies and less paper breaks

- Improves product quality in terms of strength and surface properties

- Reduces steam usage

- Increases production with quality

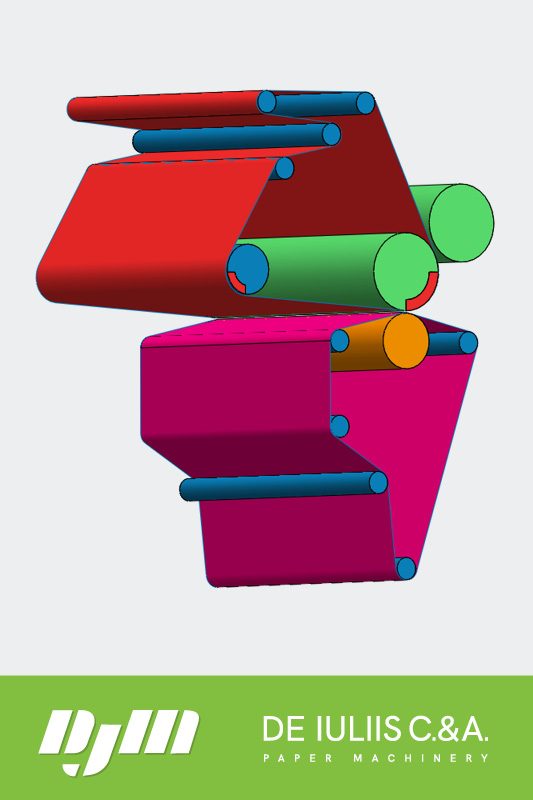

- TriNip Press

-

This type of press can be used both in the manufacture of low weight newsprint and packaging grade. The trinip is a press with three contact points that provides constant support of the sheet taken from the felt through the first three nips, eliminating free draw forces. The paper remains always in contact with one roll, so the in the press section are not required additional guide roll, reducing the press section dimension. A dry and strong sheet at the exit of the trinip helps to reduce the risk of breakage and to increase the runnability. Moreover Trinip can work at very high speeds. The double-felted first nip allows for higher press loads without crush. Trinip can be provided with a fourth press which reduces the different sheet smoothness from the two sides of the paper.

Main advantages:

- elimination of re-wetting

- increasing content of dryness after the press part

- paper guiding without free draw forces

- shortened paper track in presses

- shortened press part length

- Increasing of efficiency and runnability of the machine

- Jumbo Press

-

NIP width 60 – 90 mm

Pressure up to 350 kN/m single or double-felted.Most suitable for kraft, liner, writing & printing or

speciality paper because of efficient water removal, the jumbo press is an extended Nip press, that can bring great advantages to the paper production.Main advantages:

- Wide variability of cylinder diameters from Ø1000 to Ø1800

- High pressure pulses

- High production increasing (about 5% for each dry point gained)

- Cantilever execution for easy felt replacement

- Shoe Press

-

Nip Width: 200 – 350 mm

Pressure up to 1,300 kN/m

The Shoe Press is an extended nip press in which a shoe and a polymer belt in contact with a counter roll replace the traditional press roll pair. This configuration significantly increases nip dwell time and enhances dewatering efficiency. It is particularly suitable for packaging grades as well as writing and printing papers, especially on high-speed machines.Key Advantages:

- Nip extension up to 10 times greater than that of a conventional press

- Very high impulse, enabling more efficient water removal

- Reduced energy consuption dryer section, resulting in higher productivity

- Lower fiber densification, improving bulk properties of the paper

Double-felted first press:

- prevents crushing and allows higher loads

- Increases efficiencies and less paper breaks

- Improves product quality in terms of strength and surface properties

- Reduces steam usage

- Increases production with quality

Main advantages:

- elimination of re-wetting

- increasing content of dryness after the press part

- paper guiding without free draw forces

- shortened paper track in presses

- shortened press part length

- Increasing of efficiency and runnability of the machine

NIP width 60 – 90 mm

Pressure up to 350 kN/m single or double-felted.

Most suitable for kraft, liner, writing & printing or

speciality paper because of efficient water removal, the jumbo press is an extended Nip press, that can bring great advantages to the paper production.

Main advantages:

- Wide variability of cylinder diameters from Ø1000 to Ø1800

- High pressure pulses

- High production increasing (about 5% for each dry point gained)

- Cantilever execution for easy felt replacement

Nip Width: 200 – 350 mm

Pressure up to 1,300 kN/m

The Shoe Press is an extended nip press in which a shoe and a polymer belt in contact with a counter roll replace the traditional press roll pair. This configuration significantly increases nip dwell time and enhances dewatering efficiency. It is particularly suitable for packaging grades as well as writing and printing papers, especially on high-speed machines.

Key Advantages:

- Nip extension up to 10 times greater than that of a conventional press

- Very high impulse, enabling more efficient water removal

- Reduced energy consuption dryer section, resulting in higher productivity

- Lower fiber densification, improving bulk properties of the paper

Blog news

Projects from the past, the history of our company, which is the history of our family and the entire community.

DJM Innovation. The new system introduced in the suction roller, entirely in-house technology.

A project all our own that takes shape according to the client's specifications.

De Iuliis delivers a turnkey PM1 modernization for Raipaper, featuring a new fourdrinier, Combi Press, upgraded vacuum and dryers, boosting quality, efficiency and Industry 4.0 readiness.