Fourdrinier

PAPER MACHINE

Specifications

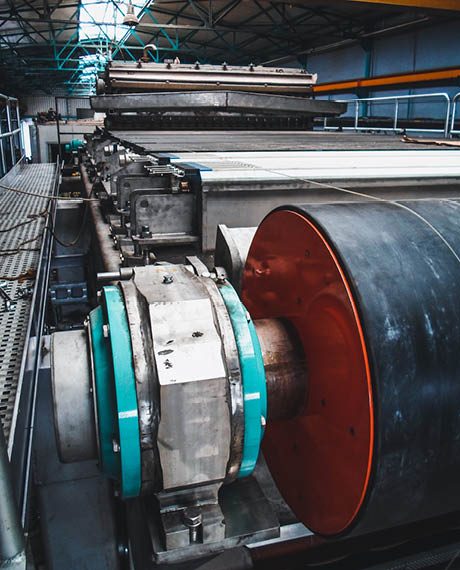

The main components that make up the forming section designed and built by DJM include:

• Cantilever frames

• Drive and breast roll cylinders with lowering systems

• Stainless steel suction rolls

• Guide rolls

• Low and high vacuum boxes

• Stainless steel doctors

• Automatic regulators

• Mechanical and pneumatic wire stretchers

• High and low-pressure oscillating showers

• Dandy rolls

DJM Former

Mould Cylinders and Mini Forming Fabrics

In addition to Fourdrinier-based production systems, DJM is capable of supplying forming systems with formers/mould roll (with or without a vacuum box) or mini forming fabrics for the production of heavy boards and specialty papers.

The modular mini-forming fabrics are ideal for the production of multi-layer boards up to 1200 g/m², and allows the reduction mould rolls required while increasing machine speed.

Main advantages include:

• Low operating costs

• Low vacuum requirements

• High productivity (30-190 g/m² per fabric and up to 1.2 t/h/m² per fabric)

• Increased productivity and speed (up to 450 m/min)

• Excellent layer adhesion

• Reduced installed power